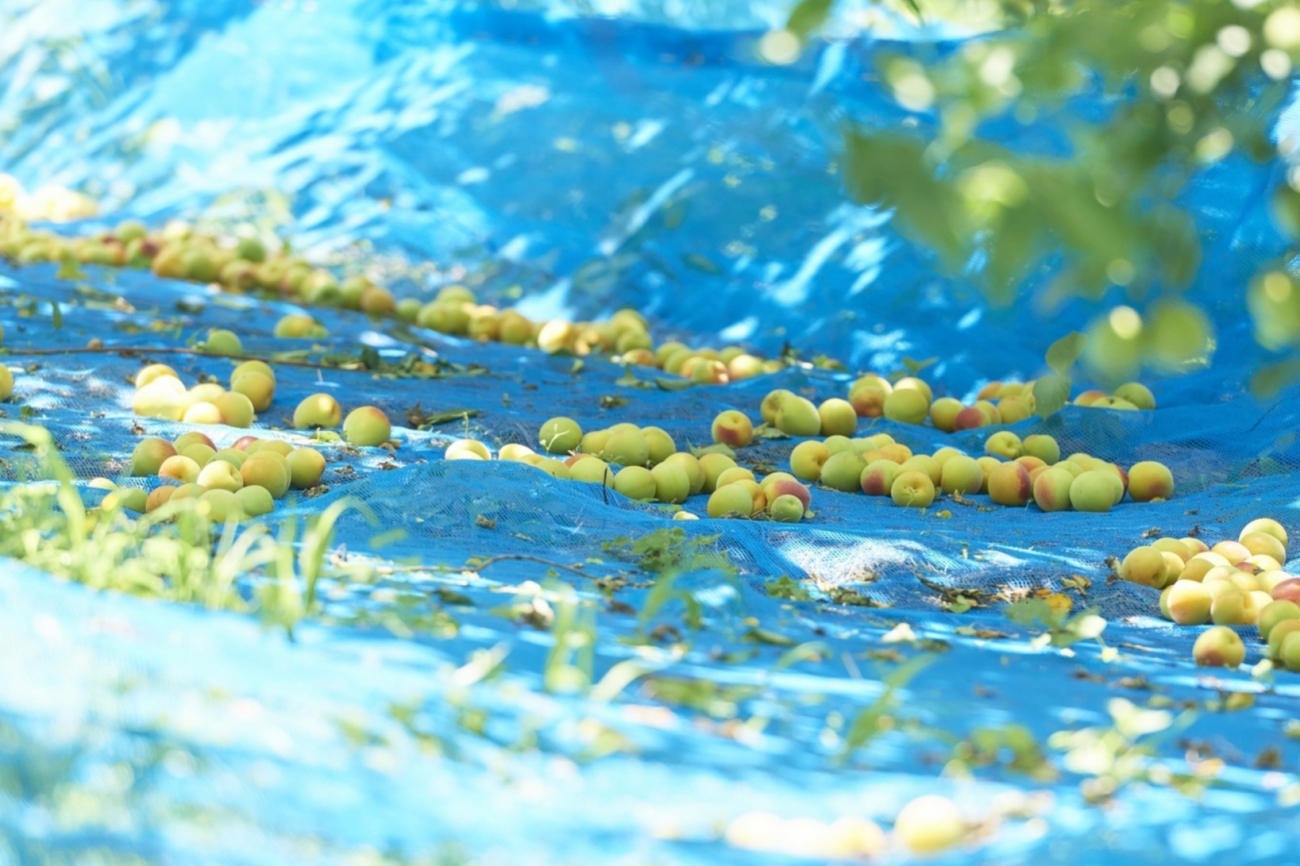

Traditional Nanko-ume plums, prepared by hand

Shima Kanko Hotel’s seasonal magazine "Shima Time" introduces the four seasons of Ise-Shima through the local culture, rich nature, and food.

Beyond refinement

From Shima Time Summer 2024 Issue

Kishu, one of Japan's leading plum production areas, is blessed by the Kuroshio Current with a mild climate and long hours of sunshine, and ume plum cultivation has flourished here since ancient times.

Nanko-ume has won renown as the highest quality plum variety. Green Nanko-ume plums are processed into plum wine and plum syrup, while fully ripened plums are mainly processed into pickled plums, characterized by their soft flesh and fruity tang and aroma.

The East Kishu region of Mie Prefecture, bordering Wakayama Prefecture, receives more rainfall than any other region in Japan, and the skin of Nanko-ume plums in this region grows thinner and softer. About 25 years ago, four plum farmers from Wakayama Prefecture cultivated ume plum orchards in Mihama, located in the southern part of Mie Prefecture, where ume plums are still produced today.

Executive Chef Higuchi and Japanese Executive Chef Tsukahara visited Matsumoto Farm, one of these farms, which insists on traditional hand-crafting methods. There, they saw farmers working in their own way, expanding the potential of local agriculture.

Growing Nanko-ume plums with a focus on perfect ripeness.

Matsumoto Farm operates three ume plum farms in and around the Mihama area, growing approximately 200 tons of Nanko-ume plums annually from about 2,000 trees on a total area of around 10 hectares.

Upon arriving at the plum orchard surrounded by mountains, the chefs saw beautiful plum buds on the trees.

"The buds turn red when the sun hits them," according to Kiyoshi Matsumoto, the fifth-generation ume plum grower. First of all, the chefs asked about cultivation methods.

Plum trees, including Nanko-ume plums, are "self-sterile," meaning they cannot be pollinated by the same species of pollen, so multiple varieties of plum trees are planted in the fields. Pollination is done on a windless day in January or February when the temperature is around 13°C, and bees borrowed from a local apiary are released into the field.

During the period between defoliation and fruiting, excess branches are pruned to concentrate nutrients in the fruit. "There is no set pattern for pruning because each tree is different in terms of the direction of sunlight, the rate of growth it has, and its size.

Also, ume trees produce a lot of branches, so in the end, 80 to 90% of the branches are cut off.

It’s a task that requires three years of experience to master," according to Matsumoto.

Instead, they’re carefully gathered by human hands and salted on the same day. Although the work is hard, it’s important to harvest the ripe plums from all three fields at the same time.

It’s also right in the middle of Japan’s rainy season, but even in the rain, we can’t rest in our battle to harvest these plums. We also don’t use herbicides in our orchards and we keep the grass and weeds trimmed, taking into consideration the nutrients that the trees absorb from the soil and the fruit that falls," explains Matsumoto.

The plums are carefully prepared, one-by-one, using the traditional method.

Next was a visit to the processing plant where the salting and sorting operations take place. Plump yellow Nanko-ume plums are taken from the salting tanks to a large wooden container called a kizara for drying in the sun.

Executive Chef Higuchi explains, "Even when pickled in salt, they have the fantastic aroma of perfectly ripe plums. Consumers are pleased to be able to have a stable supply of umeboshi plums in good condition, because they are produced at different times of the year," she says.

Sun-drying takes three days with approximately 2,000 kg of plums at a time. The plums are turned over by hand and individually checked for dryness. If it rains in the meantime, a plastic sheet is placed over the plums, and the entire process requires a lot of patience.

"Nowadays, many places dry their plums in plastic greenhouses and use easy-to-clean plastic colanders. We make our pickled plums the old-fashioned way, by drying them in the sun and using wooden containers that retain moisture well, enabling plums to be stored for several days without affecting their quality. This ensures that the skin can be bitten through effortlessly, and the flesh is perfectly soft," says Matsumoto.

After the plums have finished drying in the sun, they are checked for blemishes, size, softness, and other factors, and hand-sorted into seven ranks.

Even for the highest grade A plums, three or more small blemishes of 1 mm or less on the skin will lower the rank.

The sorted plums are carefully packed into barrels and aged in the basement for 3 to 12 months to produce shiroboshi (pickled plums with a salt content of 20%), an additive-free product made only from salt and plums.

"To achieve the traditional Kishu Nanko-ume flavor, automation is simply not an option. It takes a lot of time and effort, but we are committed to sticking with manual labor," says Matsumoto.

Japanese Executive Chef Tsukahara says, "You’ll never really understand the secret to the delicious flavor unless you actually come here. This approach—of sparing no effort or time—is something that Japanese cuisine shares. It's also fun to think about what kind of dishes to prepare using Nanko-ume plums, carefully hand-picked and produced in this region."

A new initiative to preserve tradition for the future.

"Of course I expected that harvesting and other physical work would be difficult, but when I actually became a farmer, I learned that there are many other hardships as well. When I started farming, I sold all the plums I harvested to a processing company, and the profits were so low I couldn't make a living by farming alone. So in 2010, we decided to do everything ourselves, including processing and sales."

The first step toward "sixth-sector industrialization" (as this approach is known in Japan), which includes production, processing, and sales, was to renovate a storage shed into a food processing room.

In addition to traditional shiroboshi pickled plums, he has developed products to meet diversifying needs, including low-salt flavors such as honey, bonito, and various fruits. He has also acquired a salt coordinator certification to learn more about salt.

At first, the company struggled with sales activities, but after operating booths at market events, opportunities started opening up. As he communicated his commitment and quality directly to customers, he gradually gained some repeat customers and caught the attention of retail buyers, and his products began to sell well. Today, the company opens pop-up stores 70 days a year in Fukuoka, Tokyo, and other cities around Japan, with 20 employees, most of whom are young people.

"Abandoned farmland is on the increase in the Mihama area. Since plum trees become less fruitful after about 35 years of age, we purchased abandoned land last year and planted new plum trees. We aim to grow Nanko-ume plums sustainably by replanting trees in older fields and utilizing new abandoned fields. They grow enough to produce in around 10 years," he said.

Executive Chef Higuchi said, "They’re connecting local traditions to the future with new ways of selling and bold new approaches. It’s not only their delicious food, but also the commitment and thought that goes into it."

| Executive Chef Hiroe Higuchi | Became Executive Chef at Shima Kanko Hotel in 2014 and took charge of the working dinner at the G7 Japan 2016 Ise-Shima Summit. 2017 Bronze Award Winner of 8th Annual Forestry and Fisheries Cooking Prize for "Cooking Masters" by Ministry of Agriculture. Received the Chevalier Award for the Order of Agricultural Merit in France in 2023. |

|---|---|

| Japanese Executive Chef Kyoji Tsukahara | Refined skills at Miyako Hotel Osaka (now Sheraton Miyako Hotel Osaka) at Japanese restaurants "Miyako" and “Uemachi” from 1987. Involved in serving Japanese cuisine at the G7 Japan 2016 Ise-Shima Summit. Became Executive Chef of Japanese cuisine at Shima Kanko Hotel in 2019. |

Summer Dish Delivered by Executive Chef - Hiroe Higuchi's Cooking Story

| French Restaurant "La Mer" | The Bay Suites 5F Dinner 17:30 - 21:00 (L.O. 19:30) |

|---|

Summer Dish Delivered by Japanese Executive Chef - Kyoji Tsukahara’s Cooking Story

Shimizu-style Conger Eel (Hamo Kuzu-uchi)

Ume plums, which lose their saltiness and gain flavor after quick-simmering in bonito broth, are combined with parboiled conger eel, creating an elegant dish showcasing the ume plums in the bowl.

It is planned to be included in the "Sanshisuimei" and "Takumi" courses from June to August.

*May not be available depending on shipment conditions.

| Japanese Restaurant "Hamayu" | The Bay Suites 4F Dinner 17:30 - 21:00 (L.O. 19:30) Lunch 11:30 - 13:30 (L.O. 13:00) *Lunch is only available for groups of 4 or more. Reservations required up to one week in advance. |

|---|

Back to a list of feature stories

Shima Kanko Hotel’s Seasonal Magazine "Shima Time"

Alongside these changing seasons, the seasonal magazine "Shima Time" introduces the four seasons of Ise-Shima through the local culture, rich nature, and more.